Language:

Sanicubic 1

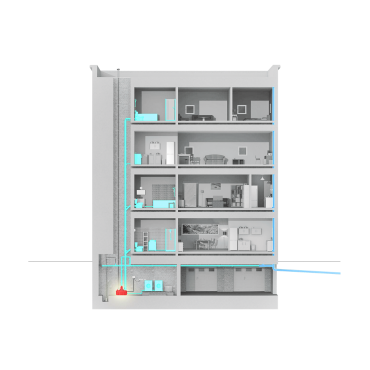

Sanicubic 1 - (IP68) Simplex Grinder lift station - 120V - 1Hp - For multiple plumbing fixtures (Residential / Commercial / Industrial)

- Powerful pre-assembled 1 HP lift station capable of discharging wastewater from multiple fixtures

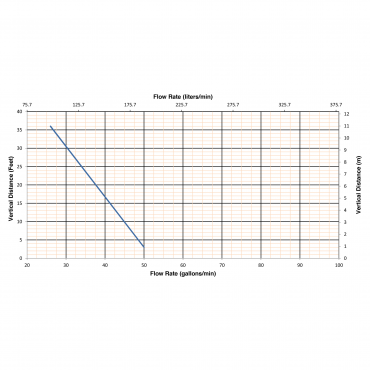

- ↑ 36 Ft ↑ and/or ← 328 Ft →

- Grinder system designed to handle sanitary products

- Rated IP68 with external control and alarm connections

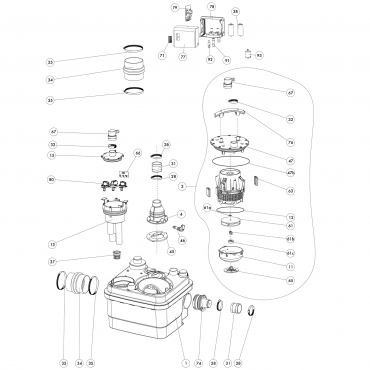

- Easy-access service panels

- Also available in 240V (Part# 069)

The Sanicubic 1 is a 1 HP heavy duty simplex grinder system used to pump away waste water from several bathrooms and fixtures from an entire building structure. This system is able to discharge the waste up to 36 feet vertical and/or 328 feet horizontal. It incorporates a grinder system which is ideal for...

See more

Sanicubic 1 Data Sheet

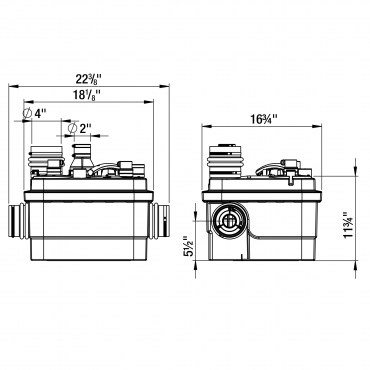

Dimensions (Height x Width x Depth):

11 3/4" x 18 1/8" x 16 3/4"

Power supply : Also available in 240 V - 60 Hz

| Technical features of Sanicubic 1 | |

|---|---|

| Part number | 089 |

| Max. horizontal discharge | 328 ft |

| Max. vertical discharge | 36 ft |

| Voltage | 120 V (also available in 200-240 V #069) |

| Frequency | 60 Hz |

| Amperage | 4.5 Amps (Max) |

| Motor | 1 HP oil-filled thermally protected motor |

| Capacitor rating | 60 microfarad |

| Operating temperature | 158°F |

| Power cord length | 80 inches |

| Noise level (measured at 3 ft.) | ≤ 68 dBA (Lp) |

| Discharge pipe diameter | 1–1/2” |

| Discharge rate | 26 GPM at 36 ft |

| Shut-off head | 45 ft. |

| Normal running time | Depends on number of fixtures |

| Capacity | 8.5 gallons / 32.2 liters |

| Inlets diameters | 1–1/2” or 4”(side), 1–1 ⁄ 2” or 4”(top) |

| Ventilation diameter | 1-1/2" vent (top) |

| Type of activation | Pressure switches, Circuit board |

| Shower/bath base height | 10” min |

| Weight | 50 lbs / 22.7 kg |

| Certifying agencies | CSA (IPC, NSPC), IAPMO (UPC) |

| Type de station | A poser |

Complementary products

Descaler - 5 L Container for all Saniflo pumps by cleaning and disinfecting -...